What Should Be Considered in Column Design?

What should we pay attention to while designing the column? Just as the human body needs bones and muscles to be able to stand, a structure needs structural elements such as beams and columns in order to stand firmly. The stronger and more properly these building elements are manufactured, the more solid and smooth the structure will be. In this article, we will touch on the working principle of the column and touch on the points that we need to pay attention to when designing the column.

What is a colon and how does it work?

Vertical bearing elements that ensure the standing of the structure by transmitting the loads and forces taken from the floor and beams to the ground are called columns. Since the columns act as a kind of bridge in the transfer of loads and forces to the ground, in case of damage to the columns, the columns cannot transfer the loads they carry to the ground in a healthy way, causing the elements on the upper floor to collapse, often causing the system to collapse.

Damages in the columns often cause not regional collapse, but the collapse of the entire system, and it is not possible to predict when the migration will occur due to brittle fractures. That is why reinforced concrete column designs are more important than other structural elements.

What Should Be Considered in Column Design and Construction?

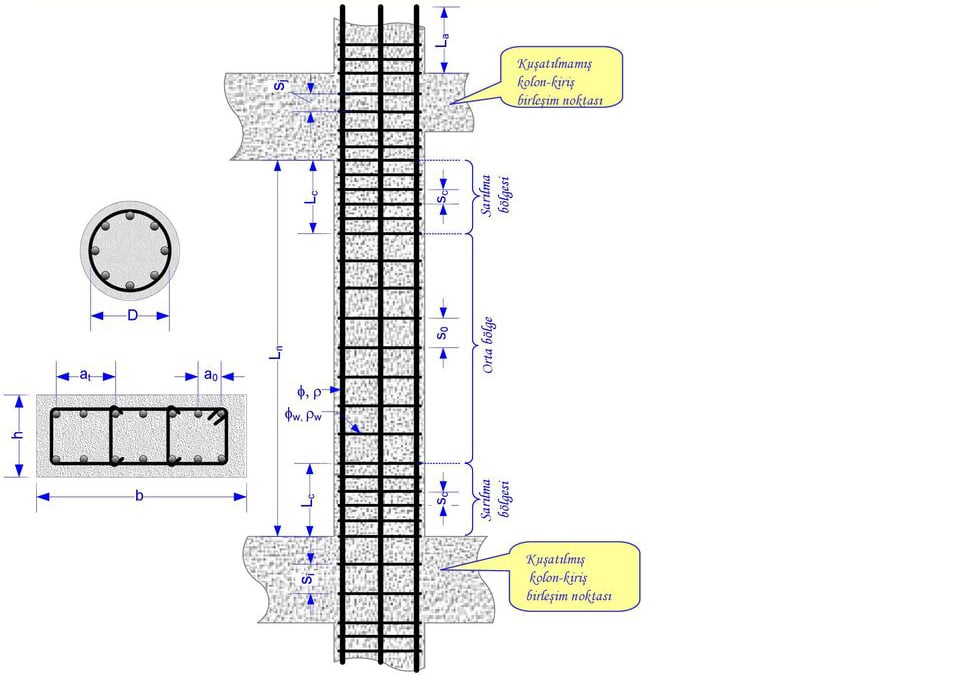

According to our TBDY-2018 regulation, the shortest side length of our rectangular columns should not be less than 300 millimeters, and the diameter of our circular columns should be at least 350 millimeters.

The ratio of the long side of our column to the short side should be less than 6.

While placing the project of our column element, we must take care to make the center of mass and center of rigidity of our structure coincide as much as possible. Otherwise , our structure will be subjected to torsion during the earthquake and will try to rotate around the center of rigidity .

In order to coincide the center of mass and the center of rigidity, the columns should be placed as symmetrically as possible with respect to the geometric center of the building.

Erosion, wave etc. Columns such as scaffolding feet exposed to abrasive forces should be designed with circular cross-sections.

The stirrup spacing in the column opening area is half of the short side of the column (bmin/2) or 20 cm, whichever value is in the safer area, should be preferred. (Note: The meaning of staying in the safer area mentioned here is which value has a smaller numerical value. According to the stirrup spacing design based on a smaller numerical value, we will obtain a more robust column against external forces since there will be more stirrups in our column.)

The stirrup spacing in the column overlap zone is one third of the short side ( bmin/3 ) or 15 cm, whichever value is in the safer area, is preferred.

The spacing of stirrups in the column wrapping area is one third of the edge (bmin/3), 15 cm, or 6 times the maximum diameter of the longitudinal reinforcements used in the relevant column (6φmax), whichever is smaller. (Note: If we are using a fret column, the design is done by choosing the smaller of this interval value, D/5 or 80 mm.)

The spacing of stirrups in the column overlapping and wrapping area should be at least 5 cm. It should not be designed smaller.

It should be noted that the diameter of the column longitudinal reinforcement is not smaller than 14 mm and the diameter of the stirrup reinforcement is not less than 8 mm.

The lap joints of column longitudinal reinforcements are in the middle third of the free height of the column.

will be held in the union territory. The size of the lap joint shall not be less than Lb. overlay

spacing of transverse reinforcement to be placed along the joint is less than 1/3 of the smallest dimension of the column and

It shall not be larger than 150 mm.

14360 Reads